Forward-looking: A team of Australian researchers has unveiled a breakthrough method for extracting gold that could dramatically reduce the environmental and health hazards long associated with mining and electronic waste recycling. The innovation, developed at Flinders University, offers a safer and more sustainable alternative to the use of toxic chemicals like mercury and cyanide, which have historically dominated the gold recovery industry.

Gold, prized for its rarity and versatility, is essential not only for jewelry and investment but also for its role in electronics, medicine, and aerospace. However, traditional extraction methods come at a high cost. Cyanide and mercury, commonly used to separate gold from ore, pose significant threats to ecosystems and human health. Mercury, in particular, is widely used by small-scale miners worldwide, often resulting in severe mercury poisoning and environmental contamination.

The global surge in electronic waste underscores the urgency for change. In 2022 alone, the world generated an estimated 62 million tonnes of e-waste, much of it containing valuable metals like gold. Yet, less than a quarter of this waste was formally collected and recycled, leaving hazardous materials to accumulate in landfills or be processed under unsafe conditions.

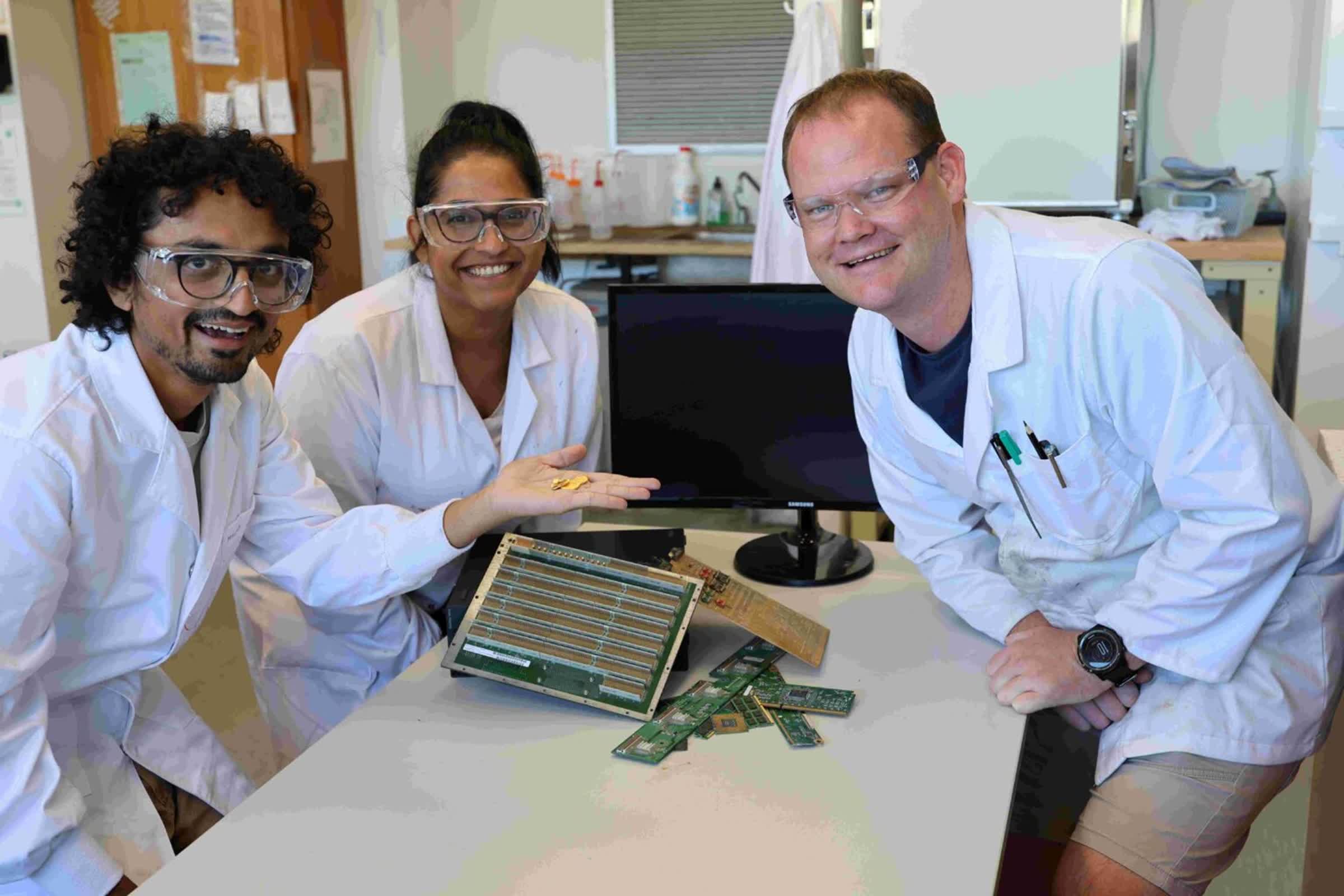

Led by Professor Justin Chalker, the Flinders University team has developed an extraction process that replaces hazardous chemicals with a compound commonly used for water disinfection. This reagent, when combined with salt water, can dissolve gold from ore or electronic waste. The dissolved gold is then captured by a specially designed, sulfur-rich polymer that selectively binds to the precious metal, even in complex mixtures.

What sets this method apart is its recyclability. Once the gold is collected, the polymer can be triggered to break down, releasing the gold and allowing the polymer to be reused. This closed-loop approach not only minimizes waste but also reduces the need for new raw materials.

The research, published in the journal Nature Sustainability, demonstrates that the technique is effective on a range of materials, from mining ore to discarded computer components. The team collaborated with experts in the United States and Peru to validate the method in different contexts, including small-scale mining operations that typically rely on mercury.

By collaborating with industry partners, the researchers aim to scale up the process and provide a practical solution for both the mining and e-waste recycling sectors. Their work not only addresses the pressing issue of e-waste management but also points toward a future where valuable resources can be recovered without compromising environmental or human health.